Description

- Electronic printed circuit board for the management of the cycle

- Frequency controller for turntable speed adjustment (from 3 to 12 RpM)

- Frequency controller for carriage speed adjustment (speed going up and speed going down can be set differently)

- Loading plate ø 1650 mm

- Maximum wrapping height: 2200 mm

- Maximum size of the pallet: 1000×1200 mm

- Maximum loading weight: 2000 kgs

- Electromagnetic brake for film stretching

- Photocell for pallet height detection

- Safety stop at the base of the carriage

- Stop at 0 position

- Power board IP54

- 4 digits display

- 2 access keys (including lock mode)

- Adjustable parameters by the control panel: cycle selection, bottom turns, top turns, rotation speed, carriage speed going up, carriage speed going down, film tension.

- Many parameters available at upper password level

- Reinforcing operation

- 3 working cycles: ascent/descent; topsheet; only ascent

- 3 programs can be saved by the customer

- “Playback” special cycle

- 2 working ways: semimanual, semiautomatic.

- Acoustic warning at the cycle beginning and stop

- Autodiagnostic

- Powder coating

- Braked turntable at the end of the cycle

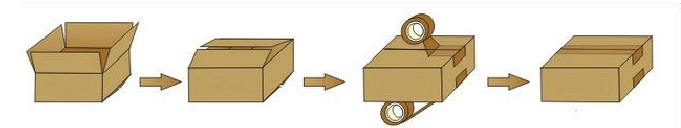

In creating Cresco, the C-One team looked at the

essential points. Cresco has only what it is really needed for a good wrapping machine:

inverter for the turntable, inverter for the carriage, film stretching adjustment,

pallet height sensor, bottom and top turns adjustment, zero position stop, three working cycles (up & down, only up, top-sheet), two working modes. 3 programs can be saved by the customer, including a completely customized cycle thanks to the “Playback” mode.

Even the structure is the result of a simplification process.

Cresco is simply the core of what you need: a stretch wrapping machine. That’s it!