Description

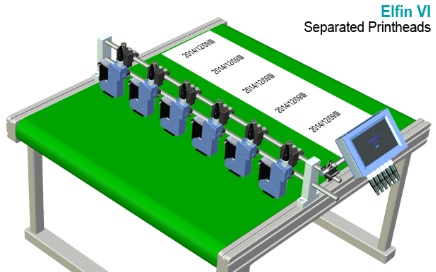

THE NEW CIJ SOLUTION

Ergonomic, reliable and flexible

The new Z4700 system conforms to the ergonomic and design tradition of Zanasi. Like all of the Zanasi product offerings, it has a robust and compact AISI 304 stainless steel IP55 cabinet without compressed air connection and can be integrated into any working environment. The hydraulic system has been redesigned to maintain high quality standards even after prolonged stoppages, to meet the demand for reliability both during standard, as well as more intensive uses, spanning several work shifts.

Higher resolution and sharpness – Lower consumption

The Z4700 is available in different configurations, depending on the application and adjustable with a variety of fonts and matrices essential to obtain high-quality prints up to 4 lines. It seamlessly integrates into production lines with print speeds of more than 2000 characters/sec. Thanks to the special UHS (Ultra High Speed) software, Z4700 can print up to 400m/min.

A new coding experience

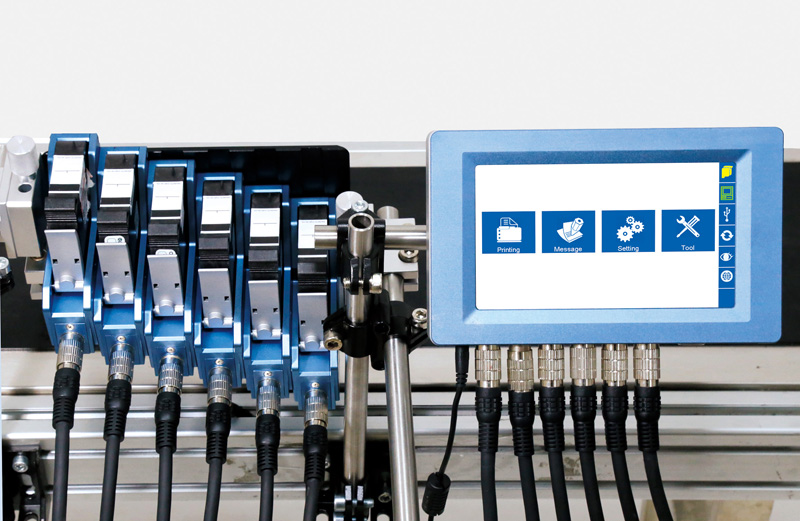

Z4700 is based on innovative management software on a stable and flexible operating system, with 10.1″ color touchscreen. A new coding experience with customizable user interface for each operator through language, keyboard and activities (multilevel login). A graphic editor with simple and intuitive icons and stretch and drag & drop functions.

Connectivity and total integration

Advanced and versatile integration via Ethernet, USB and serial ports allows access to external databases with fixed and variable type text fields enabling the system performance to be monitored remotely. A contextual help menu enables the viewing of teaching demos and information for problem solving, drastically reducing time for dedicated staff.

TECHNICAL SPECIFICATIONS

PRINTING CHARACTERISTICS

- Up to 4 lines of print

- Characters height from 0,8 to 12 mm (0,032” – 0,47”)

- Line speed capability: up to 400 mt/min (1320ft/min)

- Print rate: up to 2136ct/sec

- Messages and logos storage: up to 4 GB with expandable micro SD memory

- Up to 6800 stroke per message

- Fixed and variable text field types (with operator, automatic or external)

- Text field placing is freely selectable

- Available fonts: 5×4, 5×5, 7×4, 7×5, 9×7, 10×8, 16×10, 24×16

- Space between characters is freely selectable

- Print intensity is freely selectable

- Rapid images, shapes and lines creation

- from touch-screen display

- Automatic date, time, offsets and expiry date multifunction

- Incrementing/decreasing alphanumeric product counters up to 9 digits

- Metric repeat print – message function

- Customizable message repeat with single print start

- Field orientation: 0°, 90°, 180°, 270°

- Tower print function (Text rotation of 90°)

- Print throw distance up to 90 mm –3,54” (single line from minimum 3 mm – 0,118”)

BAR CODES

2/5 Industrial • UPC-A • CODE 39 • EAN 13 • CODE 128 (A,B,C) • EAN 128 (A,B,C)

• 2D – Datamatrix • ITF (A,B,C)

CONTROL UNIT CHARACTERISTICS

- 10,1” TFT full color anti-reflection high contrast LED touch-screen

- Stainless steel structure AISI 304

- IP55 rating, no compressed air

- Conduit length: 2 mt – 6,56 ft (4 mt – 13,1 ft optional)

GENERAL FEATURES

- Exclusive customizable user interface for single operator (functionality, language and alphabets)

- Intuitive user interface with graphic icons

- Innovative graphic editor with stretch e drag & drop functions with smartphone technology

- User interface and virtual keyboard with foreign languages and alphabets

- Automatic flushing with solvent recycling in both start up and shut down

- Low consumption thanks to the enhanced recycling system

- Message storage with file name

- Print parameters storage in the messages

- Check message dimension

- Multi-level access with login

- Report function for executed printing counter

- On line help and user manual with contextual photos and videos

PRINTHEAD

- Stainless steel and aluminium structure hermetically sealed

- Micro Print Nozzle for high quality resolution print

- Auto-phasing of ink stream for consistent print quality

- Microjet nozzle cleaning function

- Wide range of standard, pigmented, food and MEK-free inks

- Conduit inlet at 90° (optional)

- Internal Supply Positive Air Function

- 90° model for reduced spaces (optional)

EXTERNAL CONNECTIONS

- Serial connection RS232 and RS485/422

- Ethernet interface for LAN 10/100 connection

- USB port version 2.0

- Sensor management for product reading

- System ready output

- Shaft Encoder input for variable speed production lines

- External alarm outputs with traffic light column

- Parallel interface BCD, 2 bit

- Scanner connection for printed bar code validation or index message selection

ENVIRONMENT/ELECTICAL REQUIREMENTS

- Temperature: from 5° to 45° C (40° – 113°F)

- Humidity: 10 – 90{0777383fce896f6afaee31913cd4119db96601c35f16556f478c047aa53ec03e} (non-condensing)

- Single Phase, 85 – 240 Vac, 50 – 60 Hz, 100 VA