Description

The Versatile Multihead System

ModulPrint is a Large Character Printing System for the codification of secondary packaging (such as cartons, sacking, bricks, wooden cases, drums, plastic films, carton blanks etc…)

ModulPrint is an extremely adaptable and flexible machine with its own modular structure which lends itself to a multitude of applications.

ModulPrint is the proper choice for all applications with multiple production lines which have to be controlled from one console and when a number of lines have to be printed on various sides of a package (the setting of messages and printing parameters can be managed independently by means of each printhead).

ModulPrint can print logos, alphanumerical texts, expiry dates, counters, etc.

The standard software offers a variety of functions suitable for completely controlling production. Every Zanasi printing system is equipped with the Report function. This unique feature allows various production lines and coding with various printers to be controlled in real time.

ModulPrint can be interfaced directly with the most frequently used industrial devices, namely, PC, PLC, SCANNERS, ELECTRONIC SCALES, ENCODERS and OPTICAL SENSORS. With the help of a software based on Windows, the ModulPrint system can be directly interfaced to other management system by means of a PC.

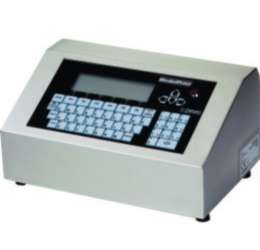

The console is very simple to use, consisting of a large membrane-type panel for industrial use, it is therefore suitable for use in particulary difficult environments. The large size graphic display lends itself to clear legibility and easy programming for messages that need to be printed.

The console is in stainless steel which makes it ideally suitable for applications in a range of harsh environments like high level of humidity, water jets or fine dust. It is possible to select six languages from the console, as well as including Arabic and Cyrillic characters by means of elaborate software.

The NZ Printhead is the ideal solution for coding in line, directly on to moving products, alphanumerical texts (expiry dates, production batches) and logos. The sectors in which it can be used are limitless due to the fact that a vaste range of inks are used. Zanasi DOD Inks are appropriate for printing on porous surfaces (paper, cartons, wood, etc.), semi-porous (leather, cement, etc.) and non-porous surfaces (PVC, polyesterm rubber, aluminium, steel, glass, ceramics and many more).

The NZ Printhead is for industrial use, entirely made of stainless steel with structural devices that render it shocks and vibration proof which can occur along the production line.

The technology of the NZ Printhead marks an advance over the traditional low definition head also called “Micro Plastic Valves”: the NZ Printhead differs in term of structural construction, printing speed, precision and lower ink consumption. It ensures perfect functioning with any type of Zanasi ink whatsoever, cutting maintenance to a minimum and therefore yielding an excellent printing result in long term.